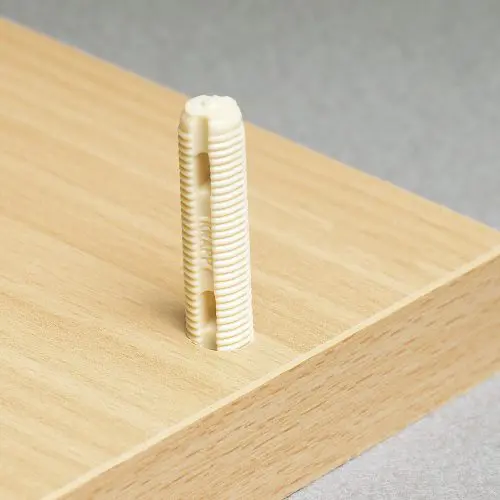

The SUNNY biscuit is a #20 self-tightening, non-visible plastic slide-in connector with integrated locking tabs and can be used in all wood materials. The two identical connector halves are simply knocked into the biscuit slot with a hammer. The patented cutting edges hold the connector in the groove with no glue required. Simply slide the connector halves into each other to carry out the assembly.

SUNNY – Biscuit Connector

$30.50 – $110.00

Description

SUNNY – Biscuit Connector

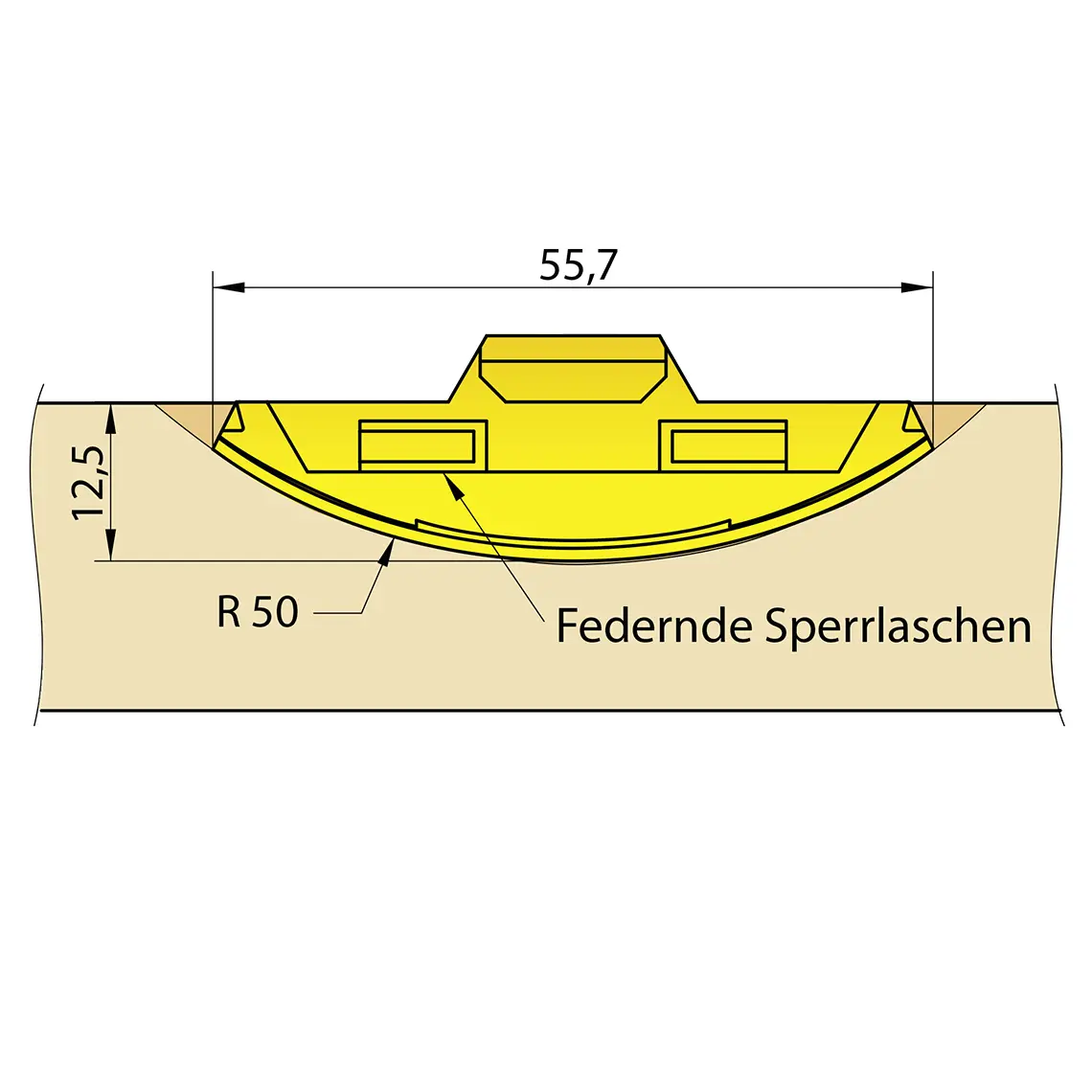

The SUNNY biscuit is a #20 self-tightening, non-visible plastic slide-in connector with integrated locking tabs and can be used in all wood materials. The two identical connector halves are simply knocked-in with a hammer following the radius of the of a #20 biscuit cut. The patented cutting edges intersect in the wood material and securely hold the connector in the slot with no glue needed to install. The components are simply snapped together without the use of glue. The joint is immediately load-bearing the moment the components are put together. Still, if the joint needs gluing, the SUNNY acts as a gluing aid and is especially useful for miter joints. The connector is self-tightening, non-visible and does not require any clamping during assembly. The locking tabs engage when the connector halves are pushed together and thus prevent the joints from forming gaps over time.

Features and Benefits:

- Fast assembly

- Components simply slide and join together in seconds.

- Reduces labor and equipment cost

- Non-visible connector

- Appeals to the architect and customer

- Self-tightening

- no need to clamp the workpiece during assembly

- prevents forming of gaps in the joint over time

- Gluing aid

- Very popular to use as a gluing aid, especially useful for miter joints.

Tips:

- Works great for RTA furniture. Note* the SUNNY latches itself due to the integrated locking tabs. Disassembly not possible!

- Used with all wood and board materials

- Recommended glue for a permanent joint → KNAPP®-Adhesive PU+ (Z011/1) or to install with the connector for reinforcement

Applications:

-

- Case Goods

- Architectural Millwork

- Shopfitting

- Furniture

- Gluing aid

- Joining baseboards and trim

Get fast and easy assembly with integrated locking tabs. The SUNNY biscuit connector is a non-visible connector that’s a game-changer for all your woodworking needs!

The SUNNY prevents gaps in joints over time and even acts as a gluing aid for miter joints. It’s perfect for case goods, millwork, shopfitting, furniture, and more. Try it out for yourself—once it’s in, it’s in for good! Get connected with the SUNNY biscuit connector today.

MaterialPlastic – PA6, fiber-glass reinforced plastic

Coatingnone

Connector typeSlide-in connector

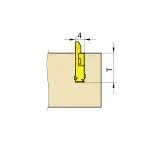

MountingKnock-in following the radius of the cutting edges

AdvantagesConcealed, self-tightening connector with integrated locking tabs

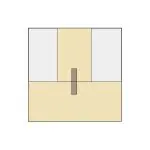

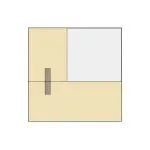

InstallationCutting a slot with a biscuit joiner (#20 slot) and adjust the depth of the slot to 12.5 mm by using the micro-adjustment screw. Insert the connector diagonally into the pre-cut slot without using any glue.

Suitable materialsAll softwoods and board materials without laminate surfaces

ApplicationFurniture, architectural millwork, shopfitting, clamping device for miter joints and corners

Videos

Installation

(View and Download Instruction Manual)

Steps:

- Make biscuit slot with biscuit joiner or CNC

- Place the connector tip at one end of the slot at an angle approximately equal to the radius of the cut.

- Press in the direction of the groove and make sure that the connector halves are inserted mirrored to each other.

- Use a hammer to knock in the SUNNY and slide along the radius of the slot. Thus, the cutting edges intersect with the component.

- Make sure that the connectors at the outer ends are flush with the surface of the component.

- To assemble the parts, first, insert and then slide the components into each other.

Tips:

- Optionally, the SUNNY can be inserted with a few drops of KNAPP®-Adhesive PU+ (Z011/1) for additional strength.

- SUNNY latches itself due to the integrated locking tabs. Disassembly not possible! The pressing pressure is about 10 kg per connection (depending on the material).

You must be logged in to post a review.

You may also like…

-

METAL – Biscuit Connector

$127.19 – $462.50 -

FAST – Biscuit Connector

$42.63 – $155.00 -

SILVER – Biscuit Connector

$96.61 – $351.31 -

CHAMP – Biscuit Connector

$44.69 – $162.50

Related products

-

TUCK – Spring Steel Compression Dowel

$6.00 – $720.00 -

CLIPS – Biscuit Connector

$59.13 – $215.00 -

KNAPP®-Dowel self-tightening plastic dowel

$47.50 – $253.00 -

Mod-eez®️ System Sets

$52.25 – $1,228.00

Reviews

There are no reviews yet.